TOOLWORX

The SUPER MAX

Production System

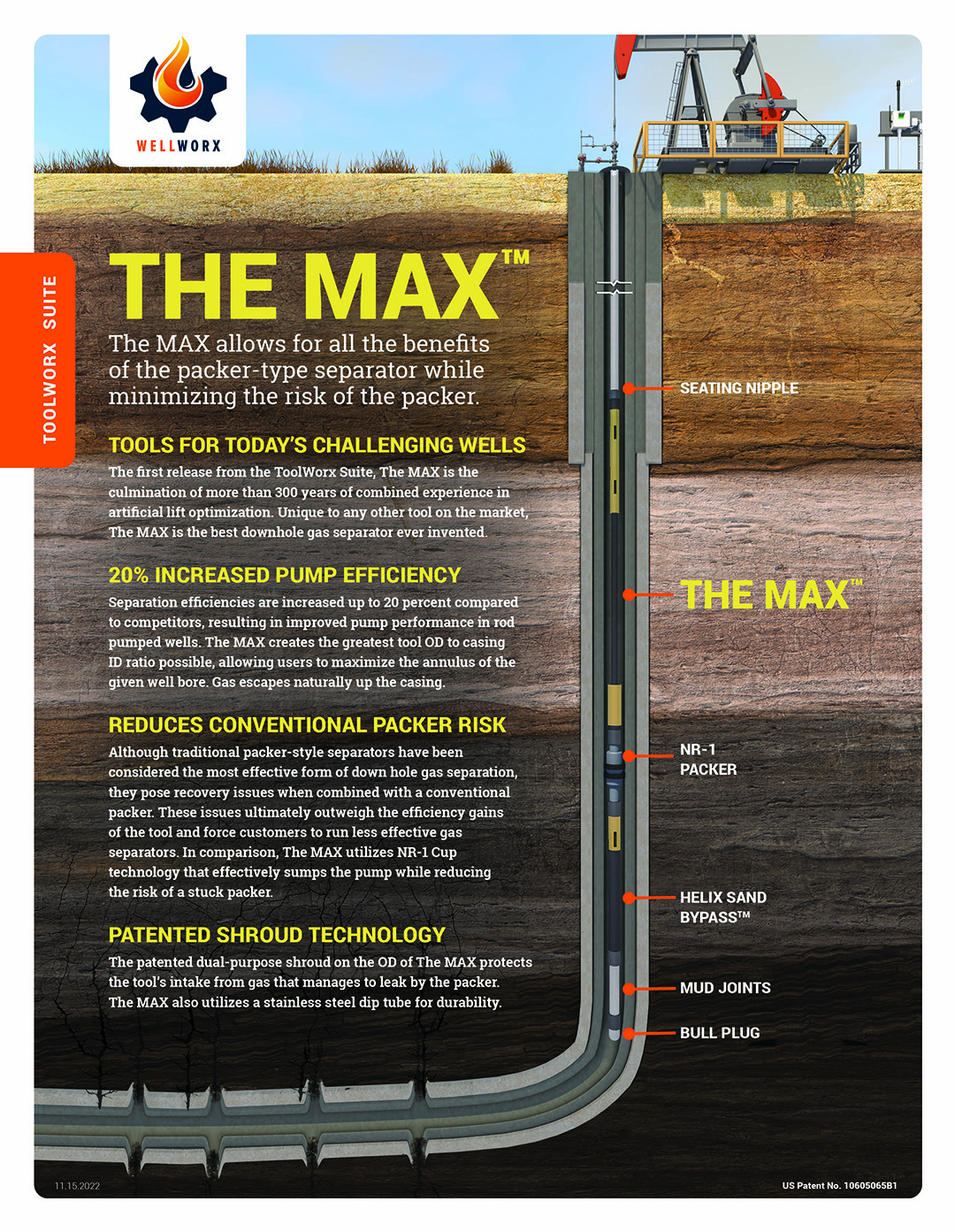

The SUPER MAX allows for all the benefits of the packer type separator while eliminating the risk of the packer.

Introducing The SUPER MAX Production System, the newest release from the ToolWorx Suite – Tools for Today’s Wells. Utilizing a NR1 Packer, the SUPER MAX’s 1.9” OD allows the user to maximize the annulus of the given well bore more so than any other tool available today. The 1.9” OD of the tool increases the size of the annulus which in turn, decreases the downward fluid velocity of the fluid prior to pump entry.

Enhancing the fluid annulus while eliminating fears and costs of stuck packers will be a massive step forward in operating and optimizing todays higher production/more dynamic rod pump wells. The increase annulus The SUPER MAX creates allows Maximized downward fluid velocities and up to 20% increased efficiencies depending on application.

The patented dual purpose shroud mounted on the OD of The SUPER MAX protects the tools intake from any gas that manages to leak by the packer cups. While protecting the intake, the shroud also serves as a cup to capture all fluid falling downwards through the annulus. This captured fluid utilizes gravitational effects to ensure the capture fluid entering the pump is gas free.

Request A Demo of The SUPER MAX Production System

DOWNLOADS

Sales Sheet

Packaging Specs

By The Numbers

The SUPER MAX ADVANTAGE

How the SUPER MAX Worx for you

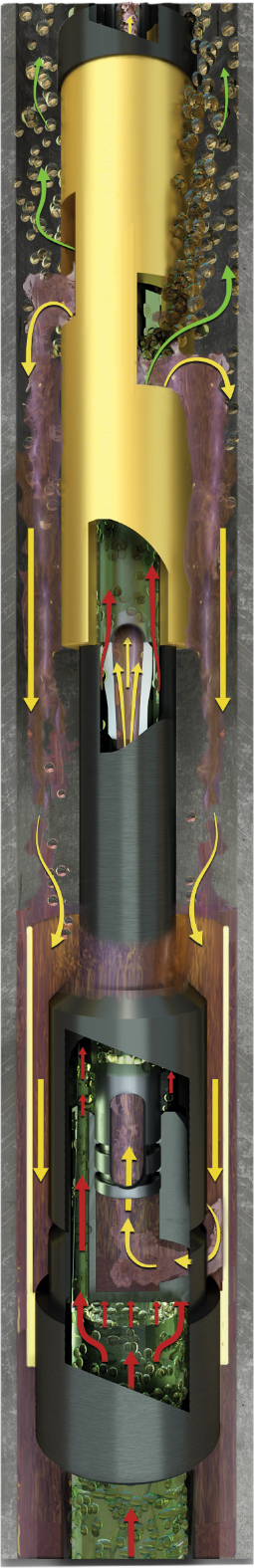

A closer look at how THE SUPER MAX technology improves performance and reduces risk.

- After exiting the solids separator, fluids and gas enter through the NR1 Packer through the ID of the tool traveling upwards.

- At the 35’ mark, the tool annulus widens to create a fluid velocity reduction prior to exiting slots to aid in minimizing turbulence and emulsions.

- Fluid then slowly spills out of the slots located at the top of the tool into the casing annulus.

- This is the moment of truth for gas separation as gas rises up the casing, while fluid falls 40’ downward toward the NR1 Packer seal and shroud.

- Gas free fluid catches in the shroud and intakes into the ID of the dip tube where it is forced upward

- The dip tube widens at the 35’ mark to again slow the fluid down prior to pump entry to reduce emulsions directly into pump.

- As fluids continue to build on the NR1 Packer seals, the shroud is protecting the tool intake from any gas leak-by that may be slipping past the NR1 Packer.

Rod Pump Applications

- 4.5″ Casing

- 5.5″ Casing

- 7″ Casing

- Conventional Wellbores

- Unconventional Wellbores

- High production scenarios

- High GLR Scenarios

- Conventional & Long Stroke Pumping Unit Wells

“Dynamic Wells Require Dynamic Solutions”

Matt Raglin

WellWorx President

Rod Pumping: Principles, Best Practices and Technologies

Registration is now open for individuals and/or teams and training is scheduled quarterly.

Sign up for email updates!