TOOLWORX

The HALO

Gas & Solid Separator

The HALO Gas & Solids Separator

DESIGNED BY THE LEADERS IN SEPARATION TECHNOLOGY

From the creators of The SUPER MAX Production System comes The Halo, the next production separator from WellWorx designed for low-to-mid-range production levels (0-269 Bbls./Day). The WellWorx Team holds 13 patents in the realm of artificial lift, 9 centered around downhole gas and solids separation. With more than 250 years of combined artificial lift analysis and problem well troubleshooting, this team has been at the forefront of artificial lift and has provided solutions currently utilized worldwide.

A THREE STEP SOLUTION

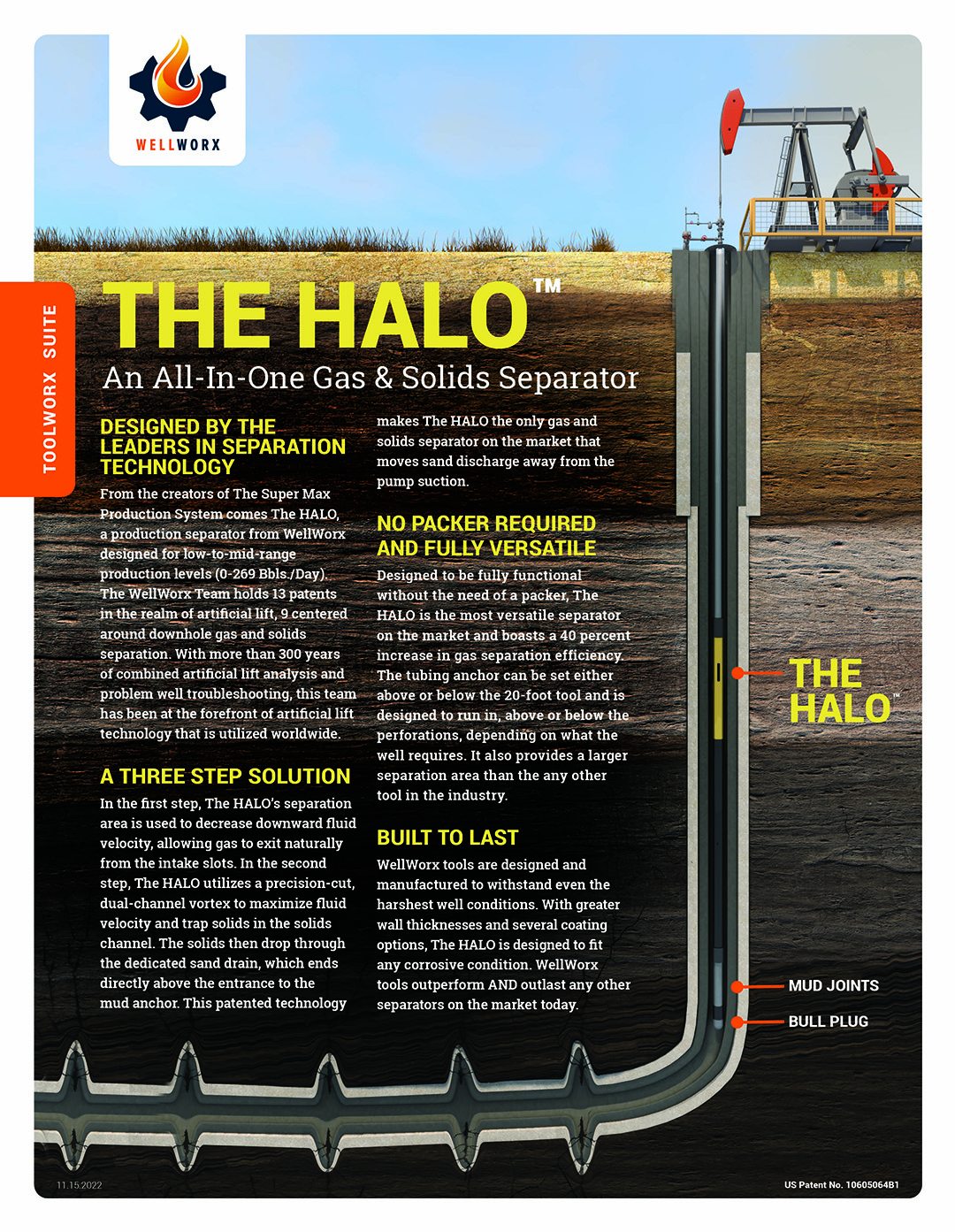

In the first step, The HALO’s separation area is used to decrease downward fluid velocity, allowing gas to exit naturally from the intake slots. In the second step, The HALO utilizes a precision-cut, dual-channel vortex to maximize fluid velocity and trap solids in the solids channel. The solids then drop through the dedicated sand drain, which ends directly above the entrance to the mud anchor. This patented technology makes The HALO the only gas and solids separator on the market that moves sand discharge away from the pump suction.

NO PACKER REQUIRED & FULLY VERSATILE

Designed to be fully functional without the need of a packer, The HALO is the most versatile separator on the market and boasts a 40 percent increase in gas separation efficiency. The tubing anchor can be set either above or below the 20-foot tool and is designed to run in, above or below the perforations, depending on what the well requires. It also provides a larger separation area than the any other tool in the industry.

BUILT TO LAST

WellWorx tools are designed and manufactured to withstand even the harshest well conditions. Greater wall thicknesses and coating designed to fit any corrosive condition. WellWorx tools outperform AND outlast any other separators on the market today.

How The HALO Worx For You

A closer look at how The HALO technology improves performance and reduces risk.

- Fluid enters the intake slots located at the top of the tool. Once inside, fluid velocity is reduced to minimize turbulence and emulsion. As fluid and solids are forced downward, gas naturally rises and exits the intake slots.

- Gas-free fluid then reaches the dual-channel spiral, which forces fluid and solids into a centrifugal motion, moving solids towards the ID of the tool barrel and into the lower solids channel while most of the lighter fluid is retained in the higher channel.

- All solids in the solids channel are drained into the mud joints via the solids drain.

- Solids then settle in the mud joint and clean, gas and solid-free fluid rises up the dip tube and straight to the pump.

Rod Pump Applications

- 4.5” Casings

- 5.5” Casings

- 7” Casings

- Conventional Wellbores

- Unconventional Wellbores

- Designed specifically for low-to-mid-range production levels (0-269 Bbls./Day)

“Dynamic Wells Require Dynamic Solutions.”

Matt Raglin

WellWorx President

Rod Pumping: Principles, Best Practices and Technologies

Registration is now open for individuals and/or teams and training is scheduled quarterly.

Sign up for email updates!