KEY BENEFITS:

- Advanced VFD Speed Control

- Artificial Intelligence

- Industrial Internet of Things (IIoT)

- PIP Control

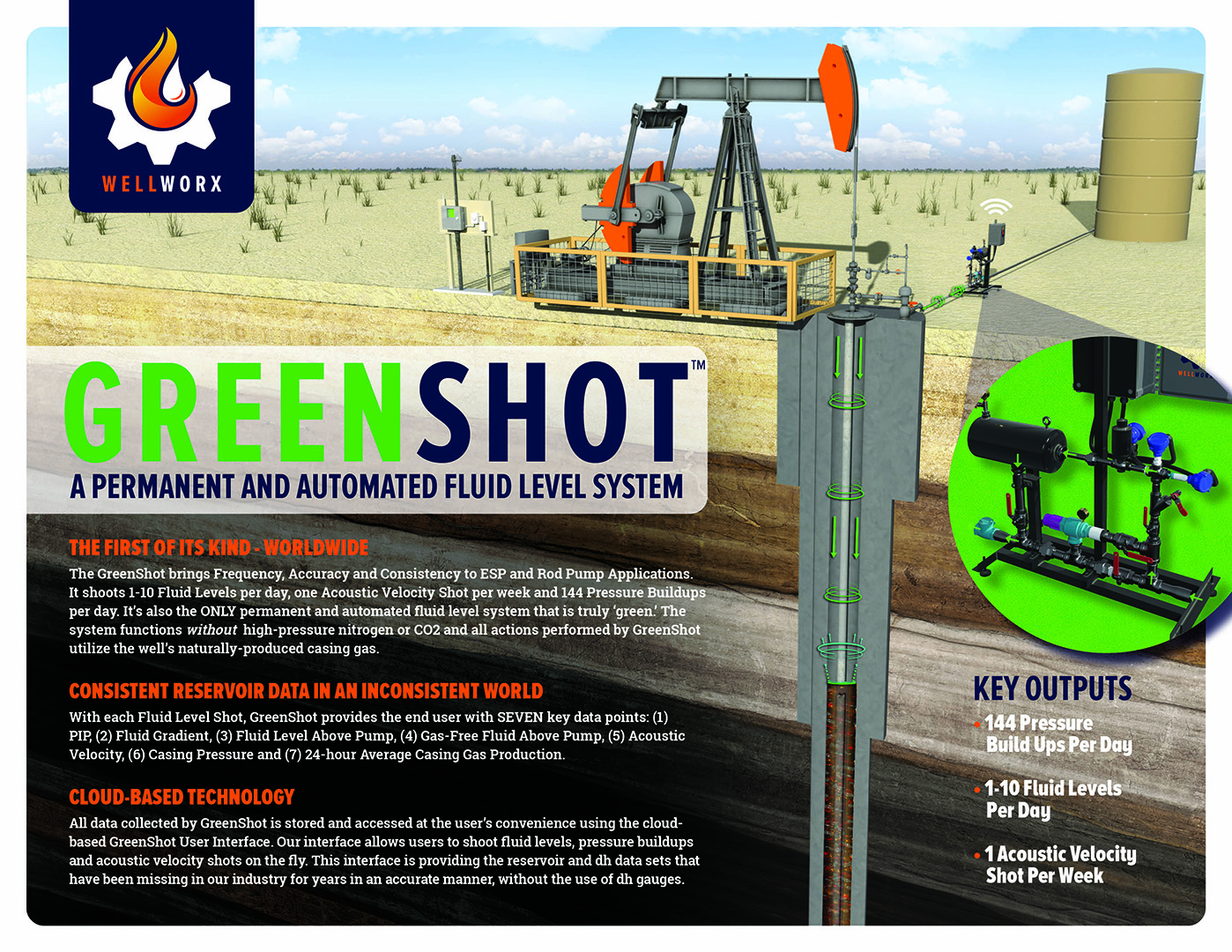

- GREENSHOT compatibility

Ken Nolen & Dr. Sam Gibbs revolutionized well optimization with their application of downhole dynamometers. Armed with their knowledge and experience, we’ve sought to continue developing this technology and leverage modern scientific advances to expand on well management capabilities. The Ken Well Manager represents our dynamic solution to diagnosing today’s dynamic wells.

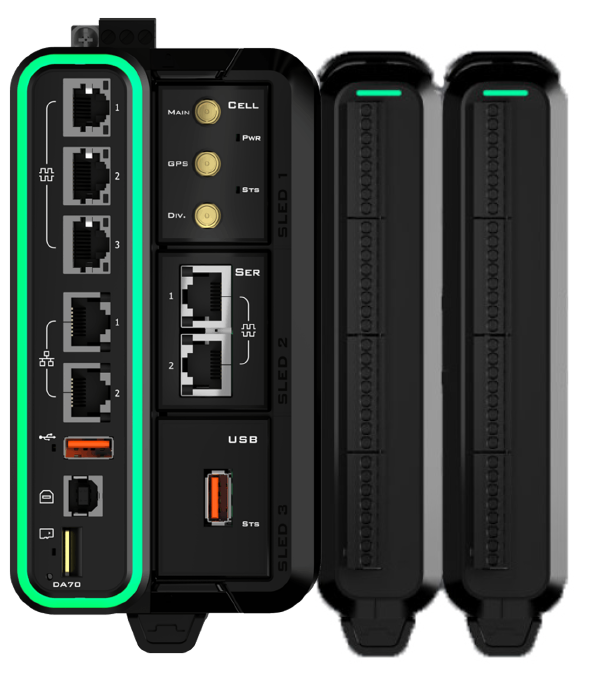

INDUSTRIAL EDGE DEVICE

The Ken Well Manager utilizes industrial hardware that harnesses cutting-edge technology and allows for sizeable expansion capabilities, advanced algorithm analysis and real-time data streaming via built-in cellular communication equipment.

DUAL-PURPOSE PLATFORM AND ADVANCED CONTROL ALGORITHMS

The Ken Well Manager and the GreenShot Automated Fluid Level Detection System were built on the same Industrial Edge Device Platform for optimal cross-product compatibility.

ROUNDING OUT THE WELLWORX OPTIMIZATION ARSENAL

Automated surface equipment like the

Ken Well Manager, GreenShot, and Variable Frequency Drives open our eyes to the whole problem so we can focus on the whole solution. Coupled with our ToolWorx product line of sand and solid separators makes WellWorx

the only choice for optimal production.

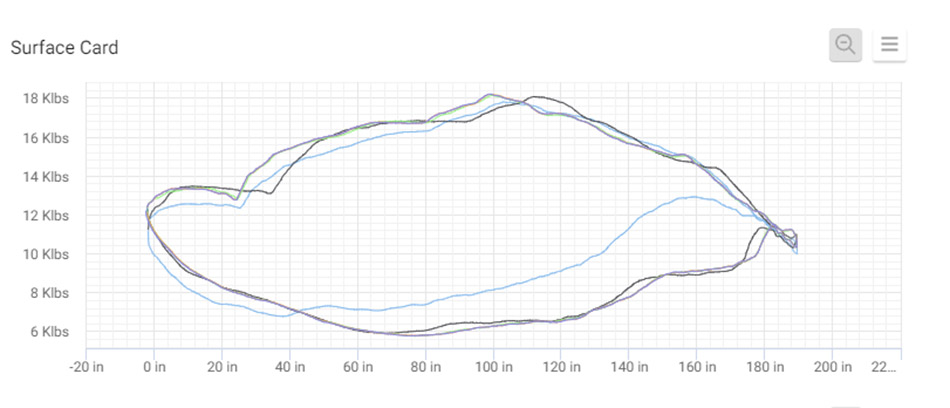

What Sets Our Controller Apart?

- Pump Intake Pressure (PIP) Control Mode

- Dynamic Pump Leakage Algorithm

- Integrated Variable Frequency Drive (VFD) mPackages

- Intrastroke Speed Changes with VFD Speed Zones

- Optional High Resolution Touch Screen

- Modular design supports up to three communications sleds and up to ten I/O modules

- Real-time data, event and security logging to microSD cord or via FTP

- Industrial construction for reliable operation

- Wide operating temperature range

IIoT edge device: the power of the future.

more than just a board!

Total Well Control

- Improved Production Calculation

- Dynamic Control Algorithms

- Integrated Liberty Lift XL Speed Control

Cost Effective, Expandable IO Platform

- (6) Analog Inputs (2) High Speed for Load and Position

- (2) Analog Outputs

- (8) Digital Inputs

- (8) Digital Outputs

- Easily expanded for even more capabilities!

Simple to use, cloud-based User Interface

- We’ve done the heavy lifting so you don’t have to!

- No SCADA system? No Problem!

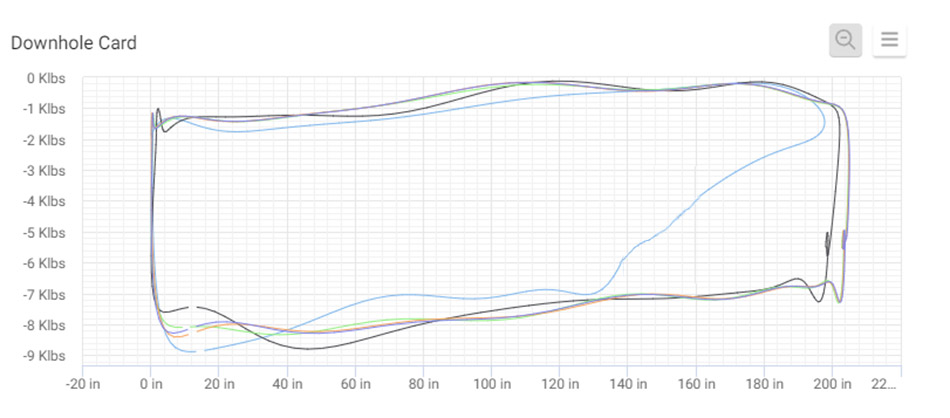

- Real-time cards

- Your data – anytime, anywhere

Cellular and Wifi Communications built-in!

- No ancillary radios or equipment necessary

- Out-of-the Box Usability

- Three months of free well monitoring included

best-in-class end devices

- The industry’s most accurate end devices

- Simple, safe, precise install

- Maintenance free with the best warranty in the industry

- No more misplaced crank sensors and bad position data

dynamic wells require dynamic solutions.

Rod Pumping: Principles, Best Practices and Technologies

Registration is now open for individuals and/or teams and training is scheduled quarterly.

Sign up for email updates!