TOOLWORX

The HELIX

Sand Bypass

The HELIX™ Sand ByPass for ESP and Rod Pump

The Most Effective and Strongest Tool on the Market

MAXIMIZED FLUID VELOCITY WITH PATENTED SAND DRAIN

The HELIX Sand ByPass is designed to work with both ESP and Rod Pump lift systems. It utilizes a pecision-cut, dual-channel vortex to maximize fluid velocity and trap solids in the solids channel, directing it to the dedicated sand drain at the bottom of the vortex. The solids then drop through the sand drain, which ends directly above the entrance to the mud anchor. This patented technology is the only tool on the market that moves the sand discharge away from the pump suction.

DESIGNED TO ELIMINATE SAND CUTTING

The operator will notice The HELIX Sand ByPass is ceramic coated, creating greater wall thickness on both the inner and outer tubes. The purpose

of this is to prevent sand erosion caused by higher fluid velocities. Our metallurgy, wall thickness and erosion mitigation makes ours the strongest tool available on the market.

TODAY’S WELLS ARE DYNAMIC.

SHOULDN’T YOUR SAND SEPARATOR BE TOO?

The HELIX Sand ByPass is deliberately engineered as a one-size-fits-all solution to sand separation. Our innovative design utilizes restricted clearance and downward fluid velocities to yield positive results regardless of production levels.

How HELIX Sand ByPass Worx For You

A closer look at how The HELIX SAND BYPASS technology improves performance and reduces risk.

- Fluid enters the intake slots located at the top of the tool. Once inside, fluid and solids are forced downward while velocity is increased. Our larger dip tube diameter reduces suction and increases downward velocity.

- Fluid then reaches the dual-channel spiral, which forces fluid and solids into a centrifugal motion, moving solids towards the ID of the tool barrel and into the lower solids channel while lighter fluid is retained in the higher channel.

- All solids in the solids channel are drained into the mud joints via the solids drain.

- Solids then settle in the mud joint and clean, solid-free fluid rises up the dip tube and straight to the pump.

- The patented sand drain ensures protection of the pump from excessive wear and abrasion, extending run times and reducing maintenance costs. Using state-of-the-art, patented drain technology, ours is the only tool on the market that moves sand discharge away from the pump suction.

ESP and Rod Pump Applications

- 4.5” Casings

- 5.5” Casings

- 7” Casings

- Conventional Wellbores

- Unconventional Wellbores

“Dynamic Wells Require Dynamic Solutions”

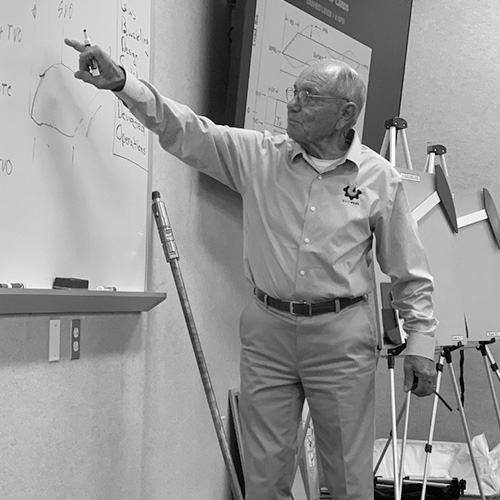

Matt Raglin

WellWorx President

Rod Pumping: Principles, Best Practices and Technologies

Registration is now open for individuals and/or teams and training is scheduled quarterly.

Sign up for email updates!