TOOLWORX

The ESP

GAS BYPASS

DESIGNED BY the LEADERS IN SEPARATION TECHNOLOGY

From the creators of The SUPER MAX Production System, The HELIX for Rod Pump and ESP and The HALO comes a new patented ESP GAS BYPASS, the newest production separator from WellWorx. Innovation and continued progress is a hallmark initiative of the WellWorx think tank and the ESP GAS BYPASS is a byproduct of our innovation methods.

Can We Extend The Life Of The Esp System, Increase Efficiency And Production?

YES we can! Avoiding motor temperature spikes due to poor gas separation efficiencies is essential. These spikes lead to shut downs, cycling of the pump/motor and, eventually, ESP system failure. Today’s wells are dynamic due to erratic inflow and chaotic gas-to-liquid ratios. Dealing with these dynamics on ESP lift is advantageous due to the increased efficiencies of the system. If the motor can be kept cool with proper separation of gas, the system can continue running and drawing the well down while the reservoir continues to unload the free gas it has built up. Production is also increased due to improved volumetric efficiencies. With this accomplished, rod pump conversions can occur sooner with better efficiency and less problematic operations.

Step-By-Step

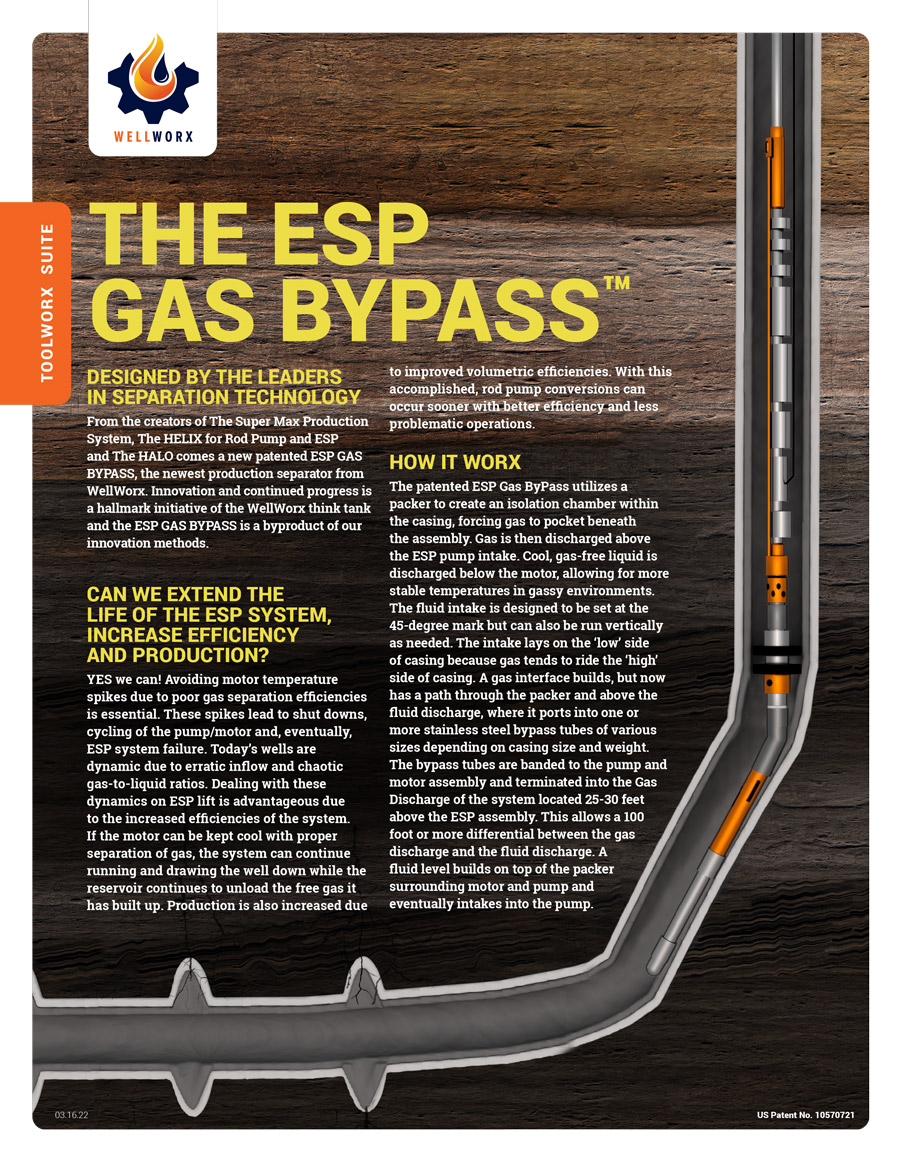

The patented ESP Gas ByPass utilizes a packer to create an isolation chamber within the casing, forcing gas to pocket beneath the assembly. Gas is then discharged above the ESP pump intake. Cool, gas-free liquid is discharged below the motor, allowing for more stable temperatures in gassy environments. The fluid intake is designed to be set at the 45-degree mark but can also be run vertically as needed. The intake lays on the ‘low’ side of casing because gas tends to ride the ‘high’ side of casing. A gas interface builds, but now has a path through the packer and above the fluid discharge, where it ports into one or more stainless steel bypass tubes of various sizes depending on casing size and weight. The bypass tubes are banded to the pump and motor assembly and terminated into the Gas Discharge of the system located 25-30 feet above the ESP assembly. This allows a 100 foot or more differential between the gas discharge and the fluid discharge. A fluid level builds on top of the packer surrounding motor and pump and eventually intakes into the pump.

How it Worx for you

- Fluid enters at intake. This can be a Helix Sand ByPass or a slotted sub. Fluid is forced downward. Solids settle in bull plugged mud joints. Clean, solid-free fluid now works its way up through the ID of the diptube, through the ID of the dual cup packer assembly and discharges above packer where a fluid level begins building.

- While the well is producing, a gas interface is building below the dual cup packer (set above KOP). This free gas enters the Gas ByPass Port and then is transferred to the stainless-steel bypass tube(s), which are banded to the ESP assembly.

- The bypass tube(s) terminate into the “Gas Discharge” portion of the tool through one or multiple ball and seat guarded ports, completing the path for free gas to flow from below the packer to above the ESP assembly.

“Dynamic Wells Require Dynamic Solutions”

Matt Raglin

WellWorx President

Rod Pumping: Principles, Best Practices and Technologies

Registration is now open for individuals and/or teams and training is scheduled quarterly.

Sign up for email updates!